As a global player with sales offices, technical support and application engineers on all continents, we guarantee worldwide advice, support and local availability.

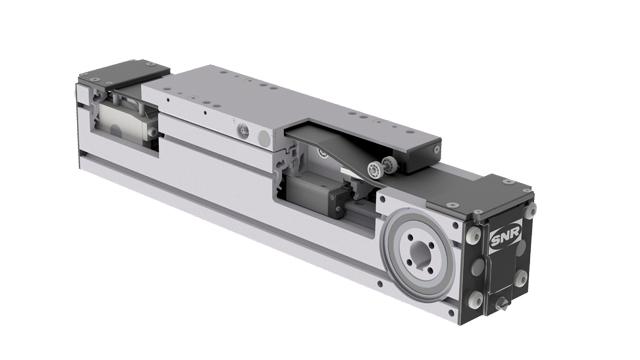

Our linear axes

Whether standardised or customised solutions – we will find the perfect linear axis for your needs.

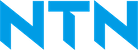

Customised linear axes

Their modular design and compatibility, even with different series, enables the user to design a simple, time-saving and economical solution for linear movements.

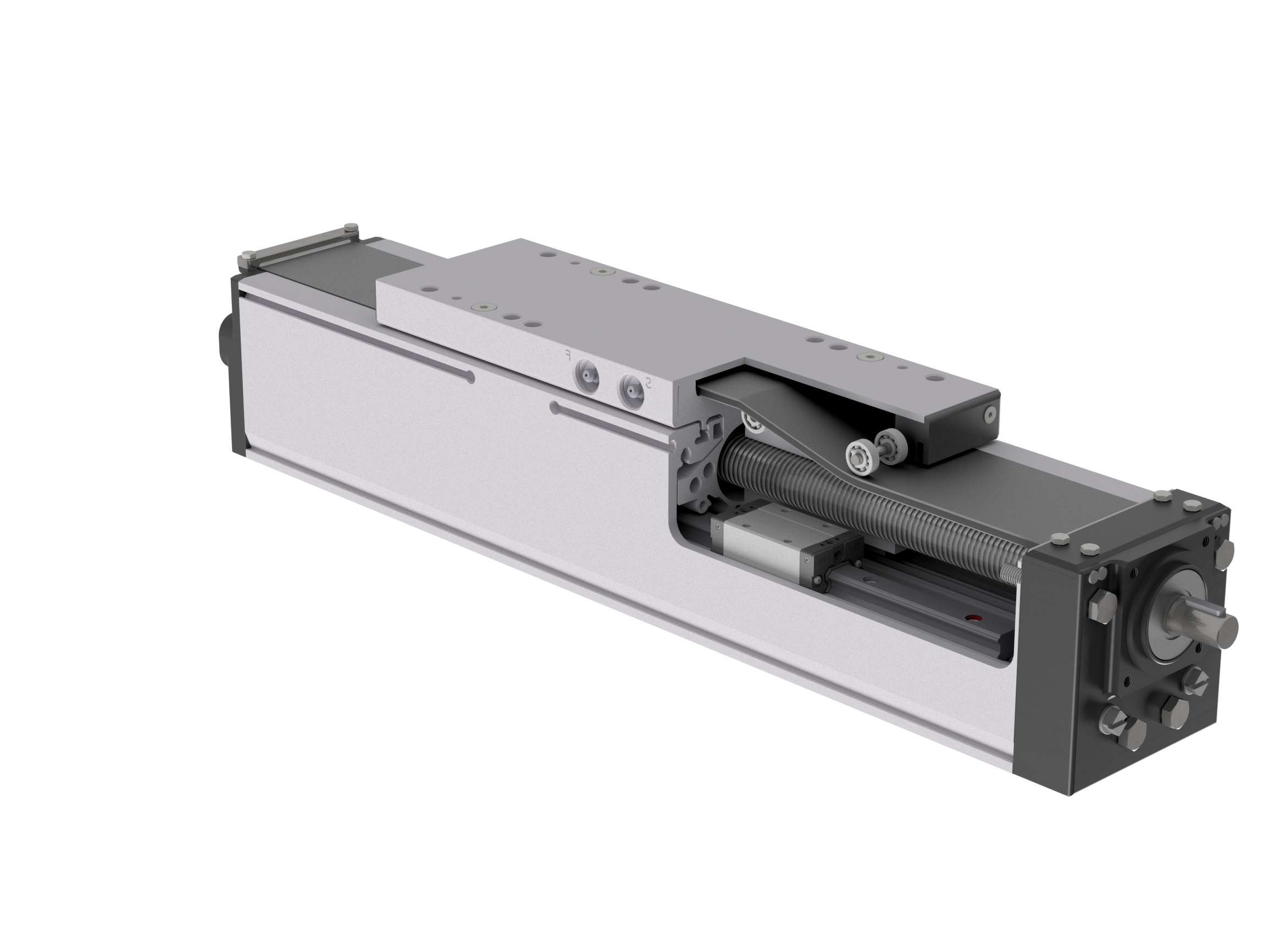

Standardised linear axes

AXE linear axes are the perfect combination of technical expertise and practical solutions for customer requirements. Our range includes all the elements required to ensure a safe implementation for the customer.

Our Benefits

What our customers say about us:

Frequently asked questions

About us

We offer you the right solution and personalised customer support.

SNR was the first rolling bearing manufacturer in the world to be certified according to the ISO 9001 standard. Since then, quality has been part of our company’s DNA. As a Japanese-German company, we stand for reliable, efficient solutions with a partnership-based relationship with our customers.

SNR has over 30 years of experience in:

- Application counselling

- Construction

- Development

- Implementation of customised solutions

Our linear axes…

- are high-quality products

- are compact and robust at the same time

- have a long service life

- offer high machine availability

- are constantly being developed and refined

Our aim is not only to fulfil customer requirements, but also to achieve real added value through quality customer support and application advice.

Our customer portfolio ranges from small users to equipment suppliers for entire automotive plants.

Request no-obligation free product advice now!

Do you have any questions or don’t know which linear axis meets your requirements?

We will be happy to help you!